Polycarbonate (PC) is a group of a durable thermoplastics that contain carbonate in their chemical structure. Introduced for commercial use in 1958, the molecular structure of polycarbonates means they possess high-performance properties, such as high impact strength, chemical and moisture resistance and its light weight. These properties make PC a popular material for a variety of applications.

PC Bottles

Polycarbonate Water Bottles used on Water Dispensers in offices and canteens

PC Chocolate Trays, Vacuum Forming Scrap

Plastic Chocolate Moulds from confectionary manufacturing

PC Lighting, Lumps & Injection Moulding Scrap

Plastic Lighting Fixtures & Fittings are often made of Polycarbonate or PMMA

Production scrap, redundant stock, sprues or purges are accepted

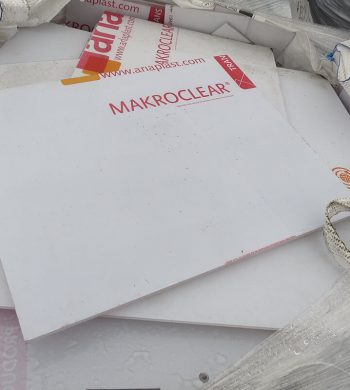

PC Sheets Offcuts, Skeletal & Trimmings

From Vacuum Forming, Signage & Retail Display industry

PC Signage Scrap

From CNC Cutting or offcuts from sign makers

Because of its chemical structure, PC plastic exhibits a variety of properties including high-tensile strength, chemical resistance, high-impact resistance, thermal conduction, UV filtration and glare reduction.

Compared to other commonly used plastics, PC has the highest relative impact strength, followed by ABS, PVC and PS.

The chemical structure of polycarbonate means that the material is transparent, lending itself to clear windows, tubes and display applications and clear moulds for casting.

PC is a widely used material, with new applications being developed regularly. Global demand for PC is in excess of 1.5 million tons each year.

Europe is a prominent market for PC, with Spain possessing the largest market share, followed by Germany, Italy and the United Kingdom.

Polycarbonate plastic is used in a range of markets including household, automotive, electronics and appliances, medical, glazing and lighting.

In the automotive industry it in commonly found in lighting, lenses, dashboards, bumpers and body panels. Many household items are formed from PC, including water dispensers, power tools, and garden equipment.

Polycarbonate, or PC, is fully recyclable. The process sees the material being shredded before it’s granulated.

PC plastic is not assigned its own resin identification code, instead it falls under ‘Other’, Group 7.

.png)